Hawker Water Less

Less is More

Less Watering

More Benefits.

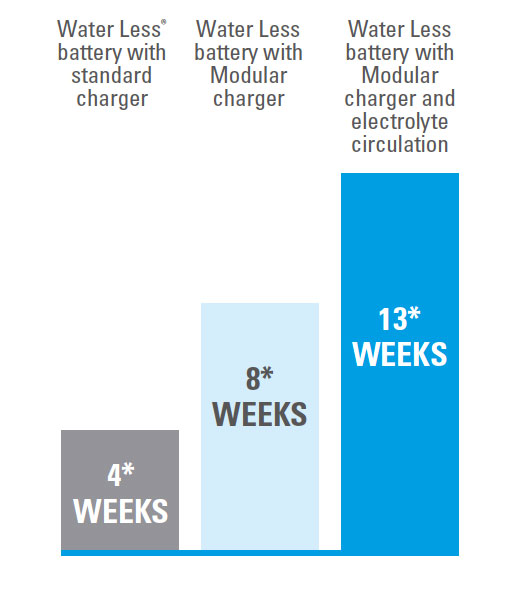

Hawker® Water Less® provides more flexibility and more time due to longer topping up intervals of 4, 8 or 13 weeks depending on charging technology. This means reduced labour costs for topping up batteries – up to 60 % (with Hawker® 50 Hz chargers) and up to 75 % (with Hawker Modular chargers).

Hawker Water Less traction batteries provide a high level of power and reliability for all industrial truck applications; even in the most extreme ones thanks to the extended capacity range. Hawker Water Less range is at the leading edge of battery technology and brings added efficiency to your business. A low electrolyte level indicator fitted on the battery informs the user of the battery when water topping up is needed.

Cell Construction

All Hawker Water Less cells use proven PzS technology. The positive electrodes are die cast tubular plates (PzS) and advanced components used in their manufacture provide increased efficiency.

The negative plates are flat pasted plates. The separator is of the microporous type.

Constructional specifications like a larger electrolyte capacity, a reduced prism height and new flip top plugs ensure added value for our customers.

Options

- Hawker® AquamaticTM: The Aquamatic water refill system makes it possible to top up all the cells from one central point through an integrated system.

- Battery Fleet Management: EnerSys® offers a solution that makes managing your battery fleet straight forward and affordable. BSI40TM and Life network iQTM are the spearheads of battery fleet management, enabling charging room management and communication with state of charge monitoring. Totally customizable to your needs, these solutions will make your energy and facility management easy and efficient.

WI-IQ® AND MODULAR CHARGER CONNECTIVITY

A further option for Water Less® batteries is Wi-iQ® monitoring device range, which precisely manages the state of charge and operating conditions of the battery as well as storing complete data of the battery’s service life and meaningful providing fleet management reports. Wi-iQ direct communicates with Hawker Life iQ™ Modular chargers, enabling battery temperature control and making it possible to work in cold environments.

ADVANTAGES (COMPARED TO STANDARD LEAD ACID BATTERIES)

- More time: longer topping up intervals

- More flexibility: suitable for 50 Hz and HF chargers

- More savings: reduced electricity cost when used with Hawker Modular chargers

- More duties: suitable for all applications

EVEN MORE APPLICATIONS

Hawker Water Less batteries are suitable for use in the following Material Handling applications

- Counterbalance trucks

- Reach trucks

- Pallet trucks

- Order pickers

- AGV/LVG

ELECTROLYTE CIRCULATION (EC)

Hawker electrolyte circulation system, using the AirLift principle, consists of a pipe system which is fitted in the cells. A diaphragm pump sends a low rate airflow into the cell which creates a circulating air stream inside the cell box. This system prevents electrolyte stratification and the battery charging is optimised. Electrolyte circulation provides optimum performance, reduces recharge time, helps keep the battery cooler and maximizes battery service life in more arduous operations.

MORE FLEXIBILITY

The charging technology must be tailored for the characteristics of the battery and the application. This is a crucial factor for the economic operation of the batteries. Hawker Water Less traction batteries are suitable for 50 Hz and HF smart chargers.

Hawker Modular chargers adapt automatically to: capacity of the battery, voltage of the battery (Life iQ Modular), depth of discharge of the battery. This means a high level of flexibility for the customer. The topping up intervals (based on 80% DOD C5, 1 cycle per day, and 5 days per week) can be achieved as follows:

- 4 weeks with conventional 50 Hz chargers

- 8 weeks using Hawker Modular chargers

- 13 weeks when the battery is equipped with electrolyte circulation and when using Hawker Modular charger